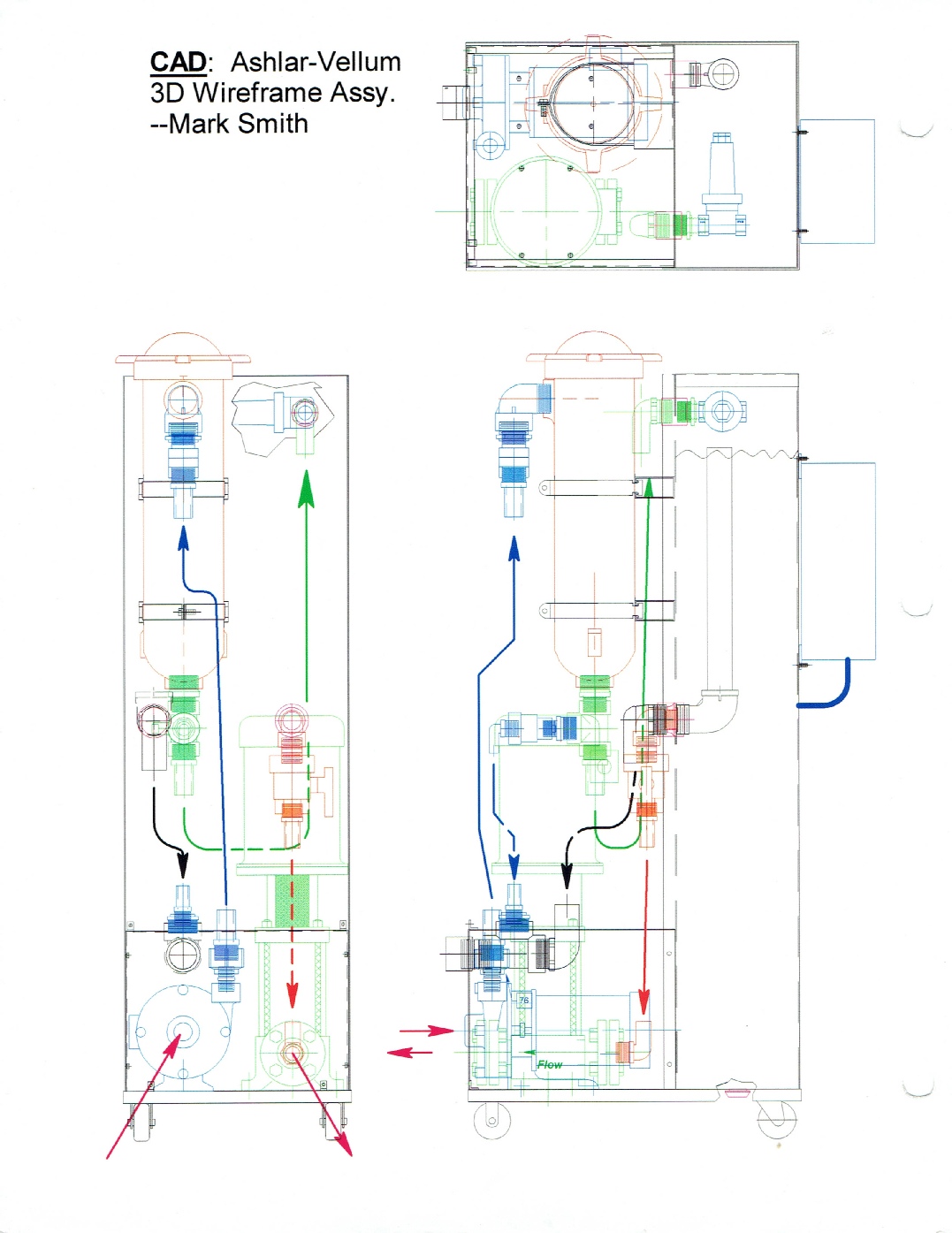

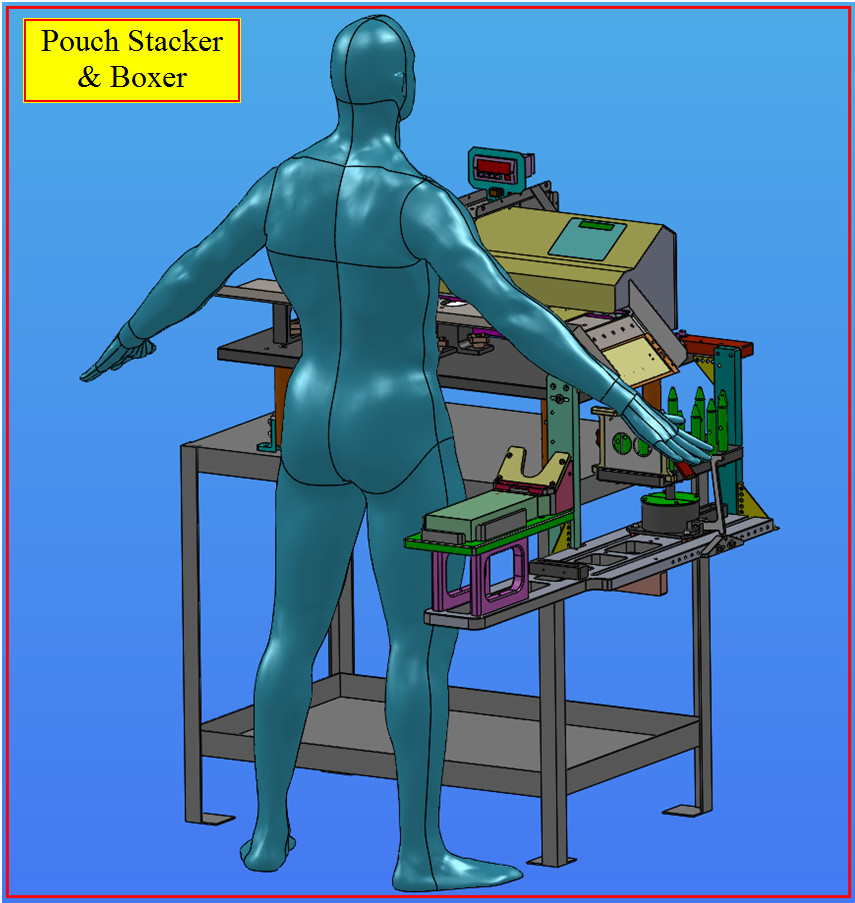

Videos: Click for several short animations / videos.

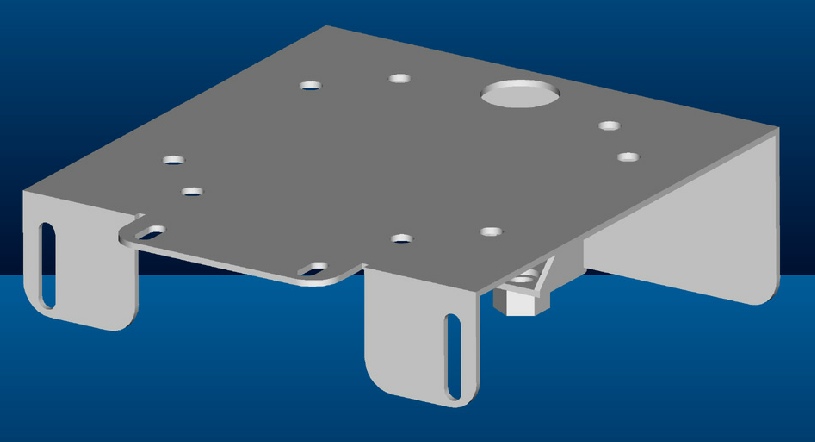

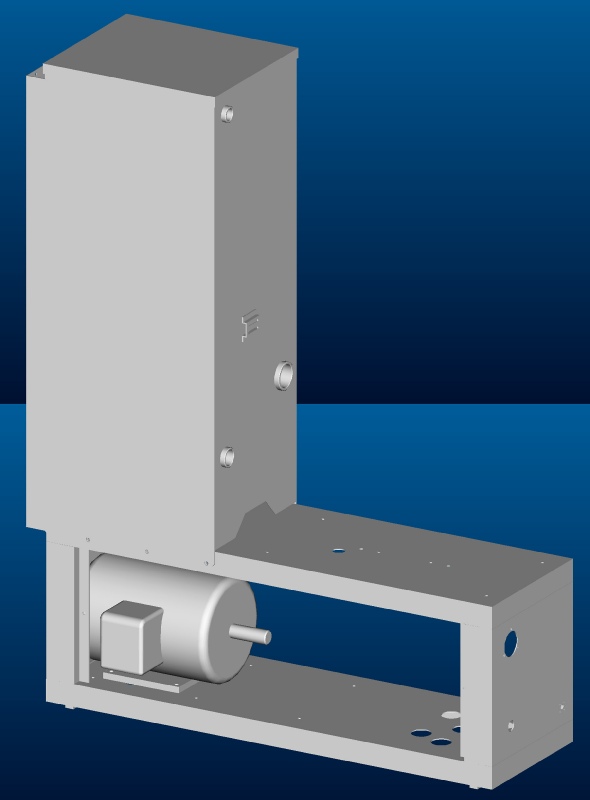

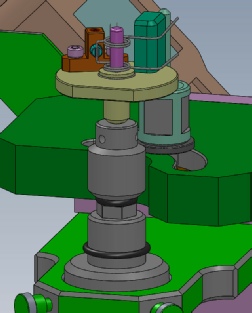

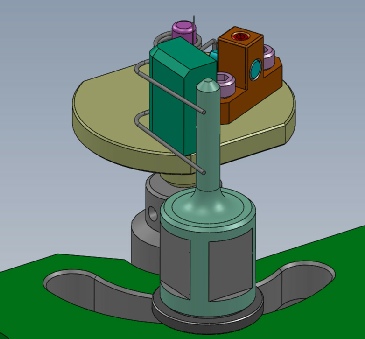

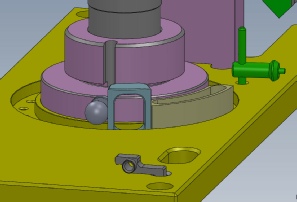

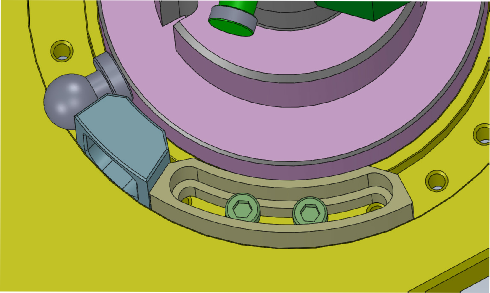

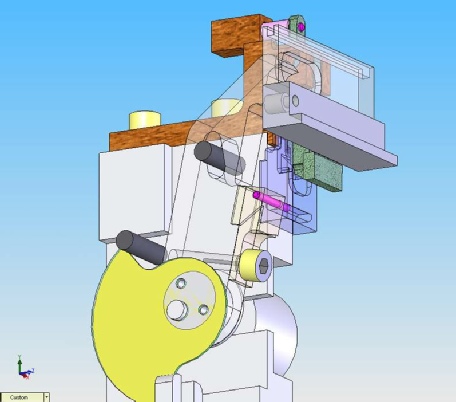

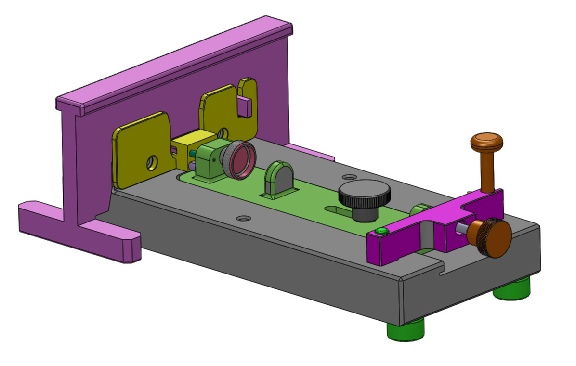

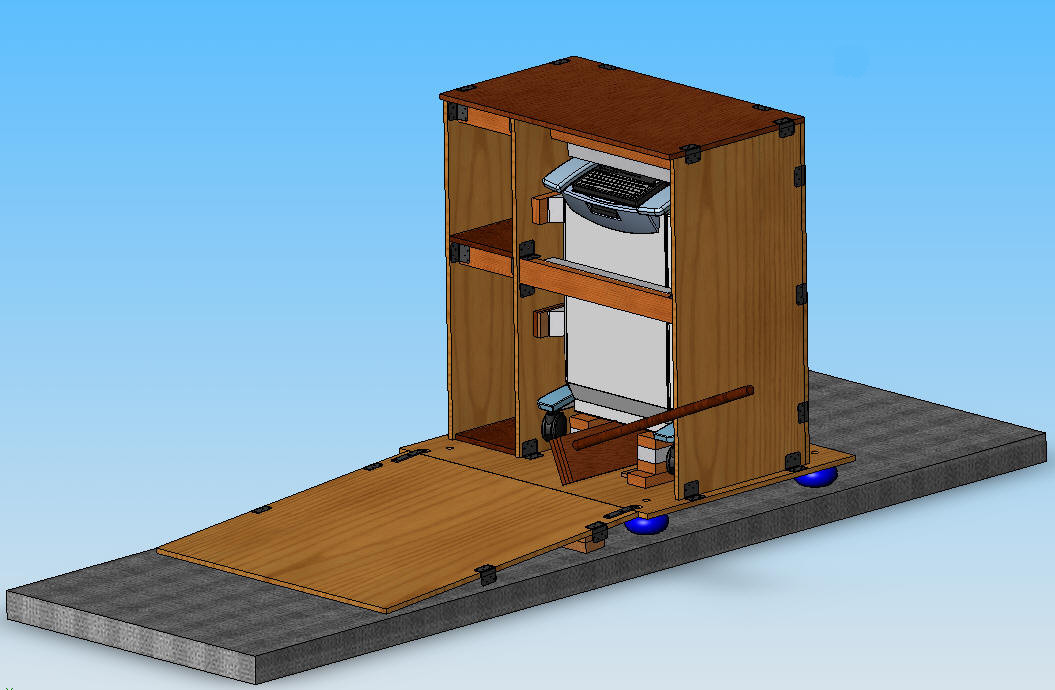

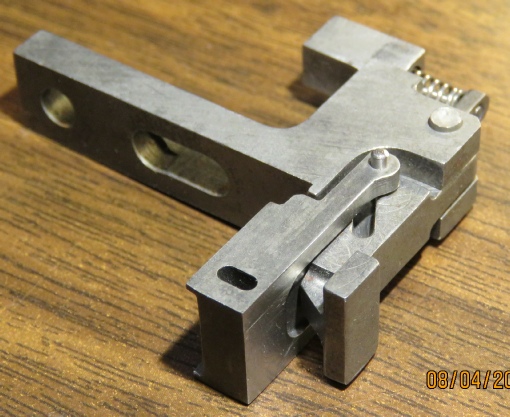

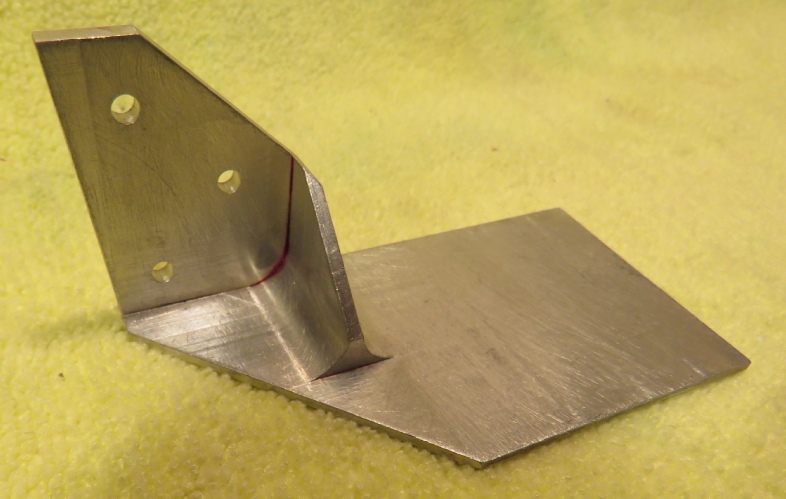

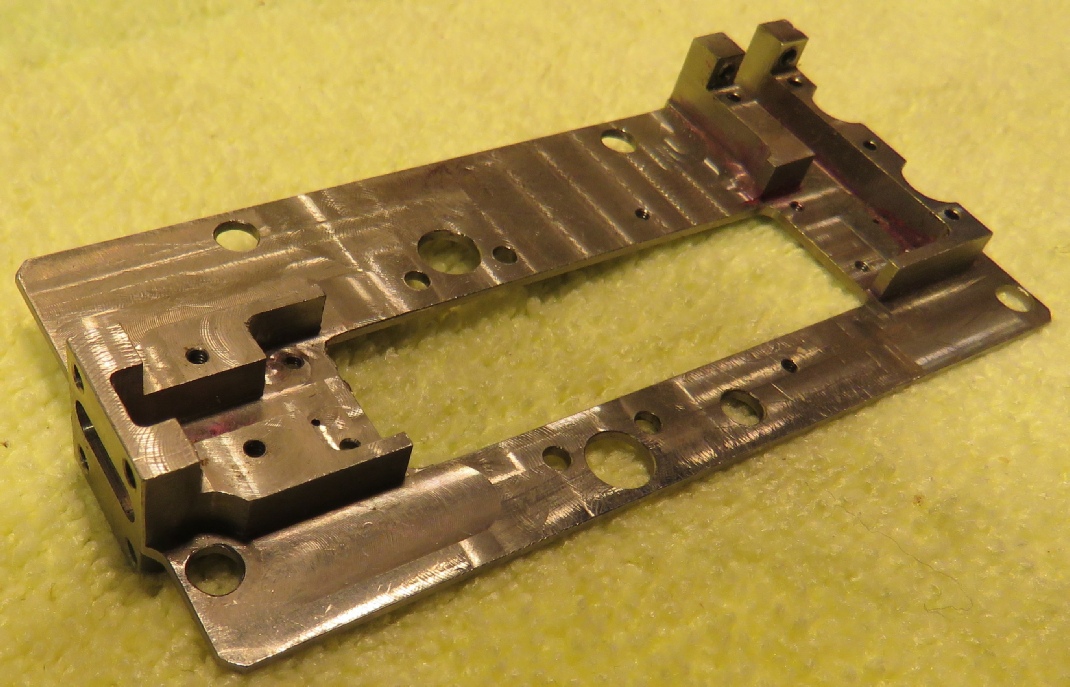

Hinged Swing Plate

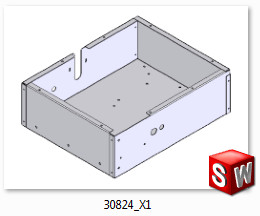

Custom Shipping Crate

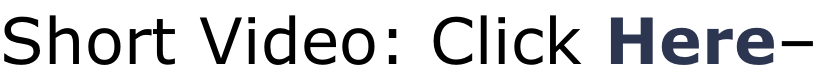

Click to see the Instruction Manual for more details on this unique design.

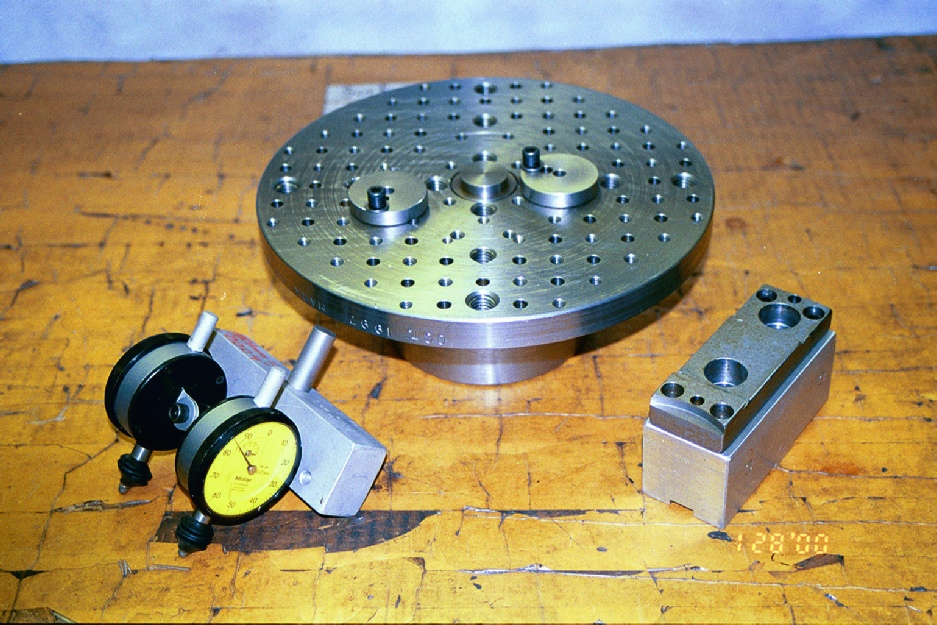

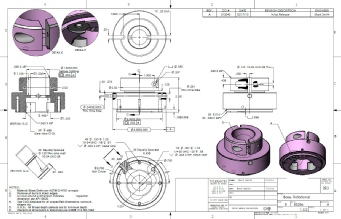

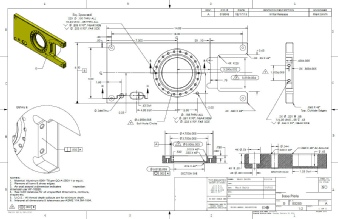

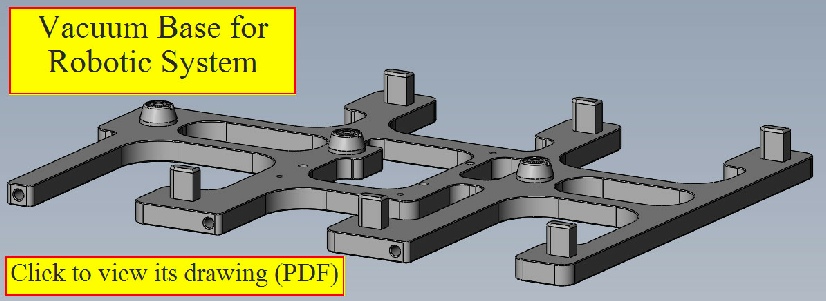

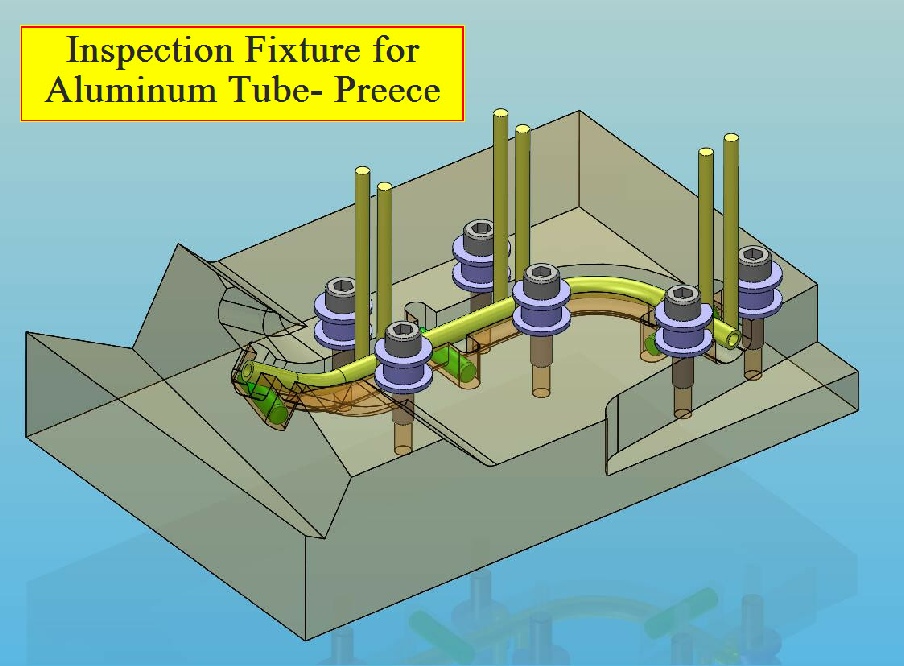

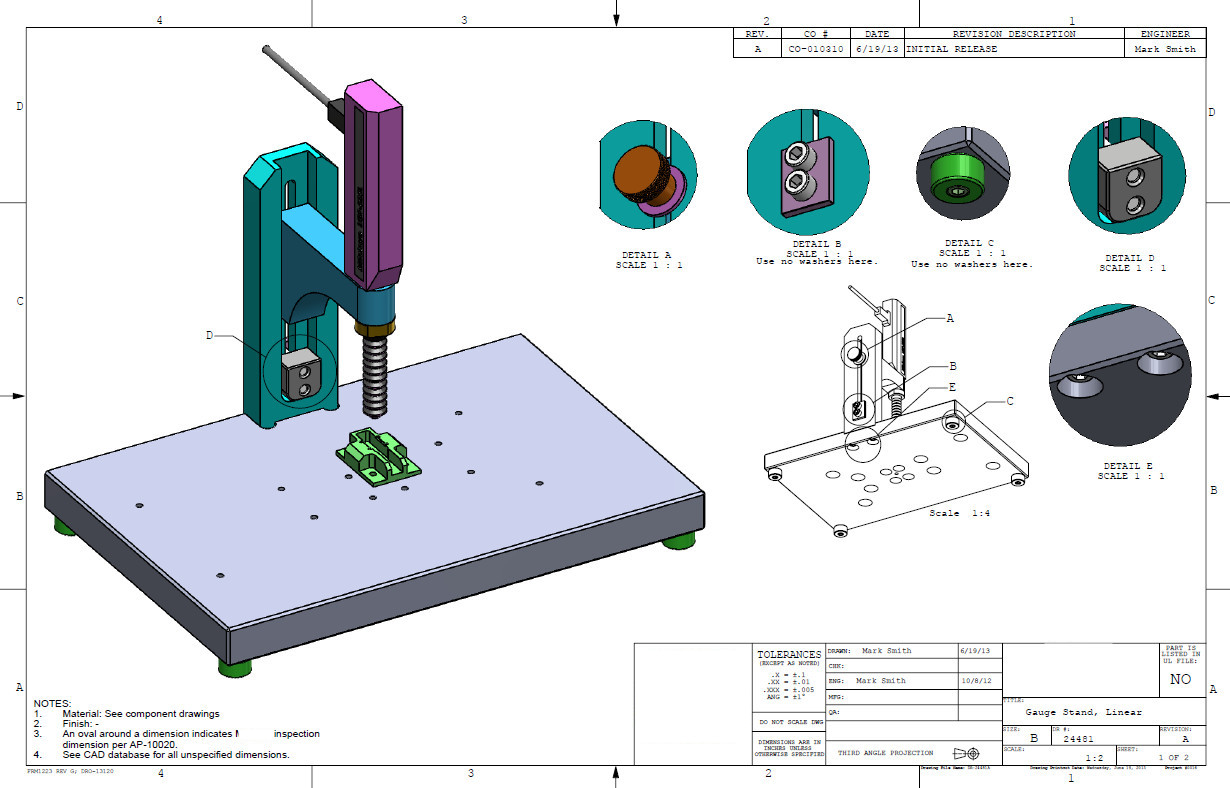

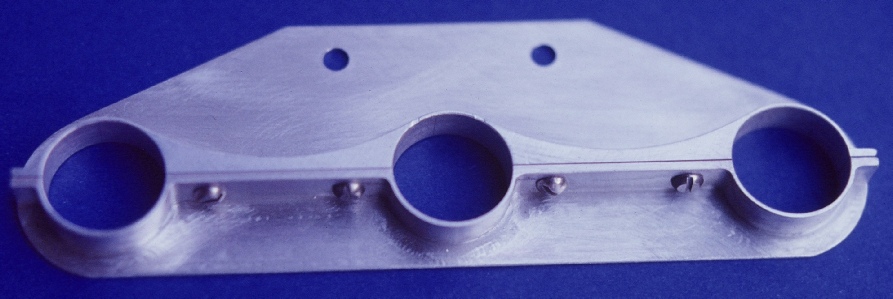

Mat’l: 6061 Alum.

Req: Flat w/i .002”

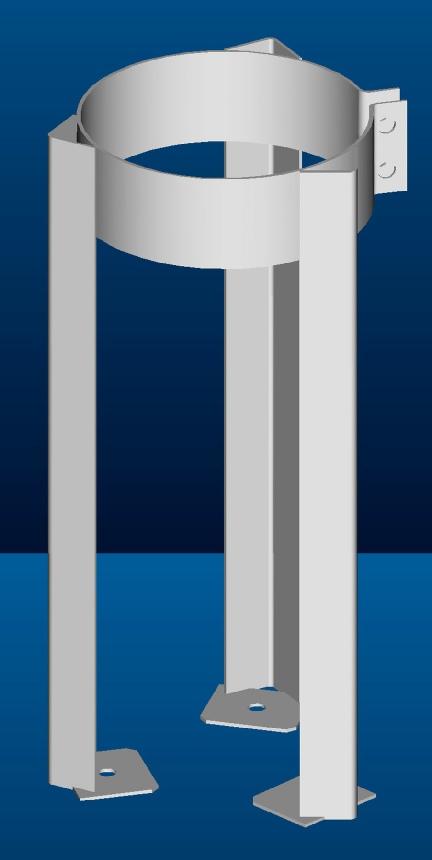

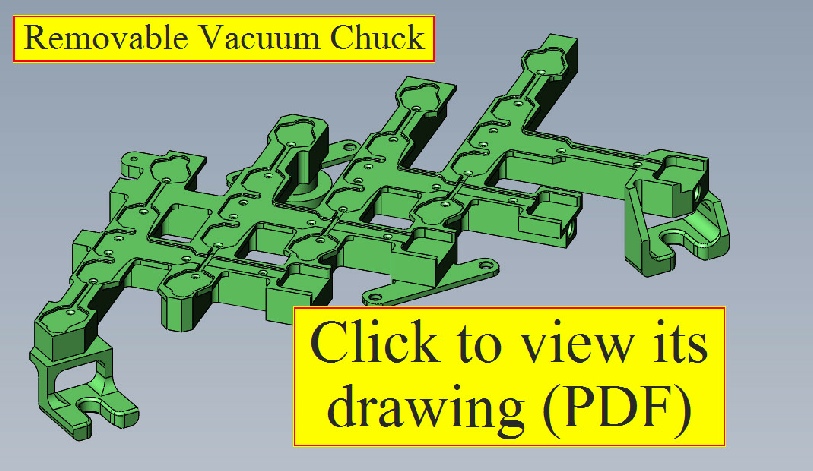

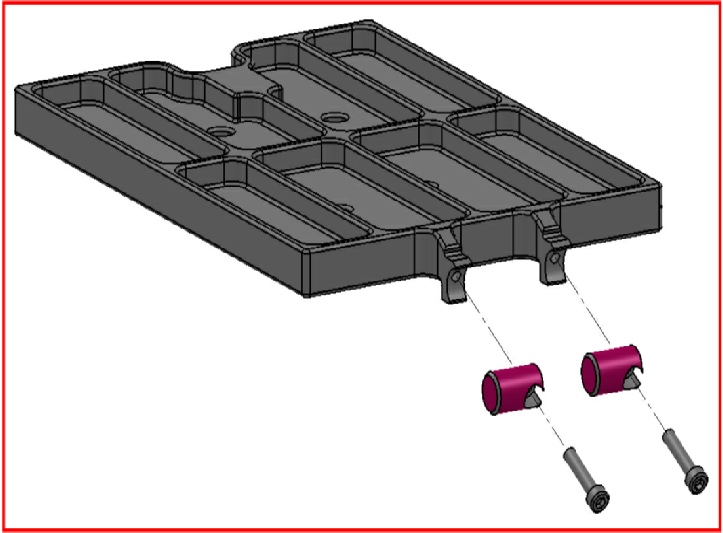

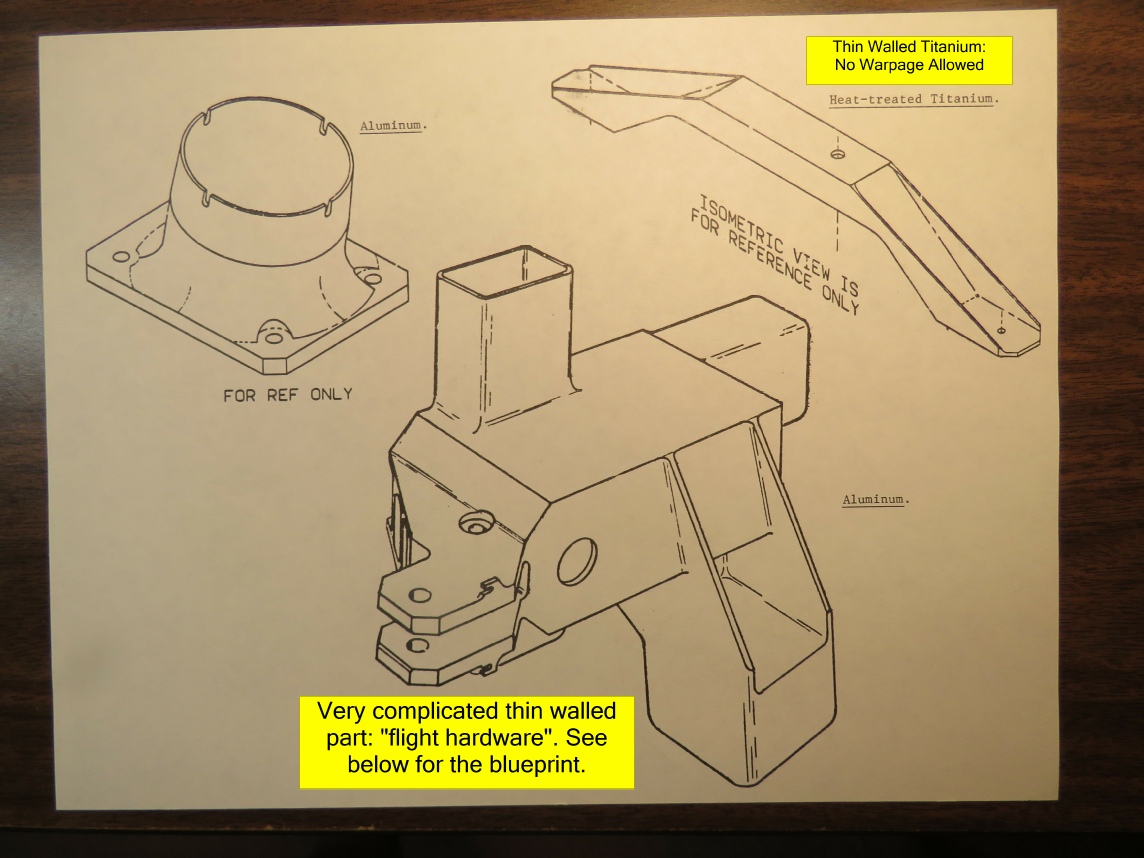

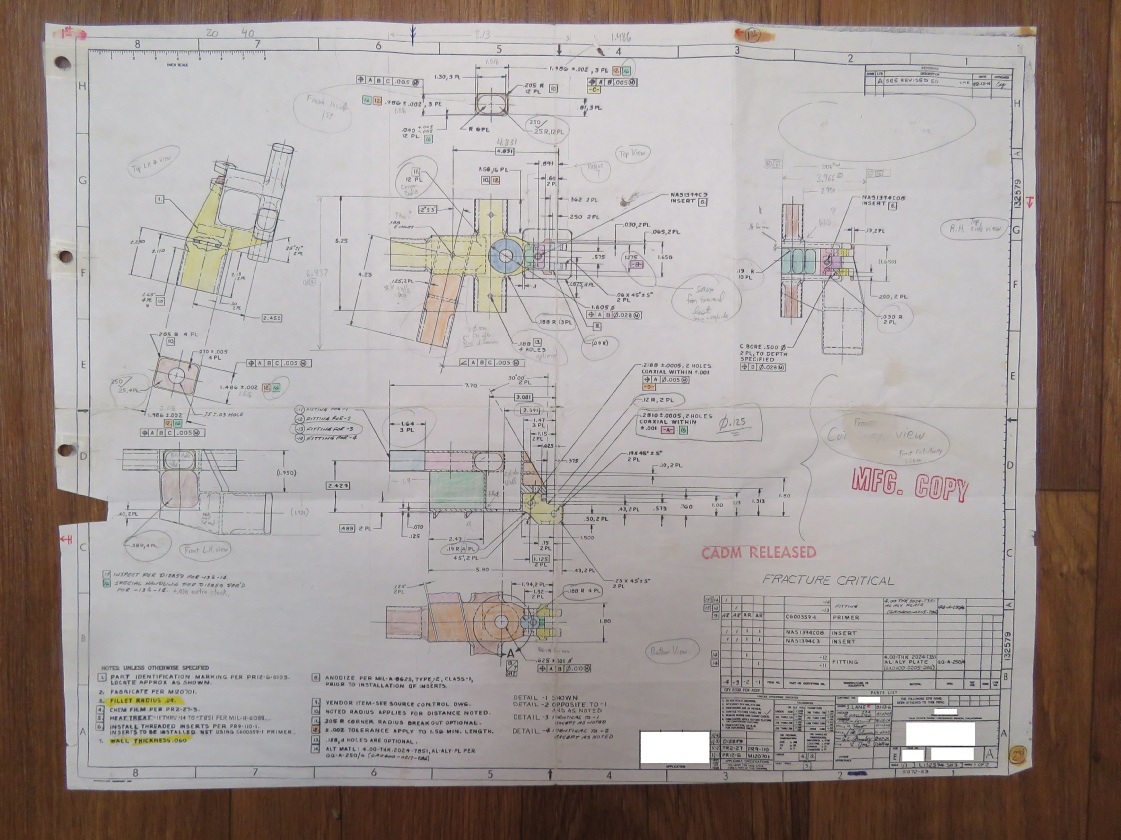

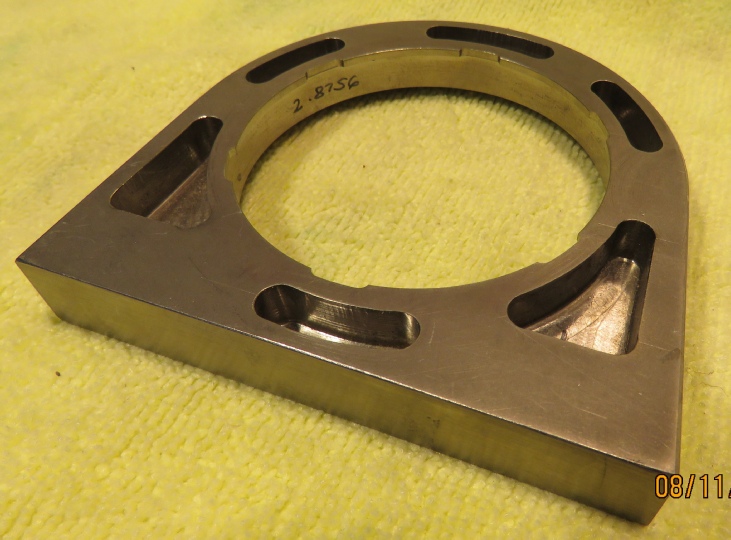

Mat’l: Alum.

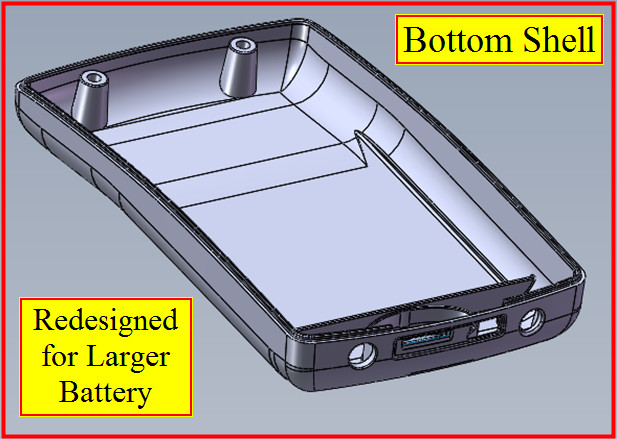

Req: Thin Wall w. No Warpage

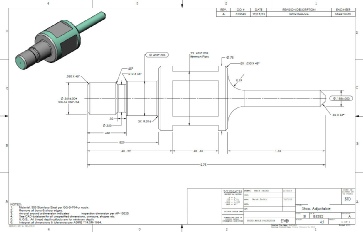

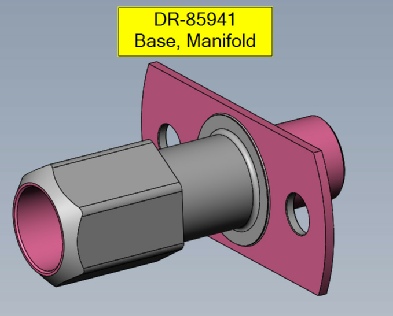

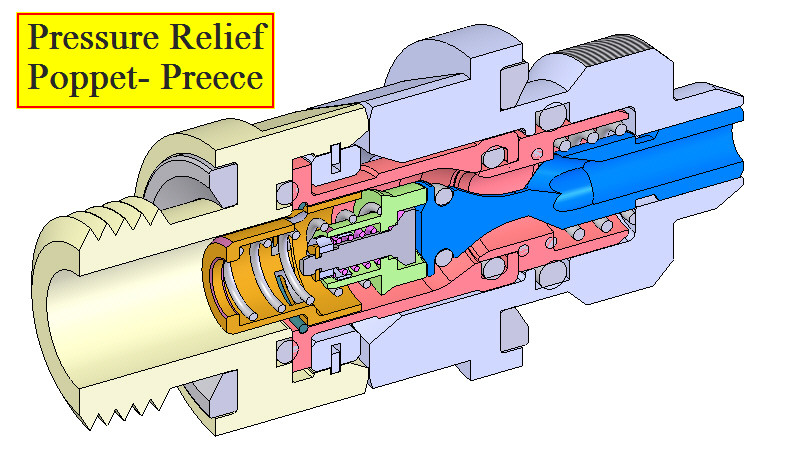

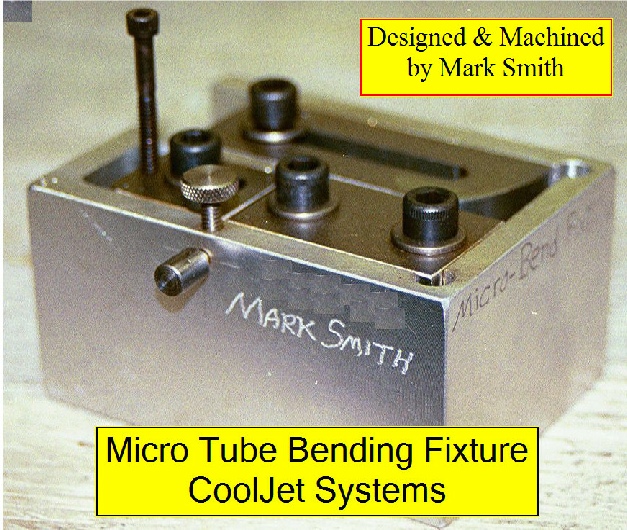

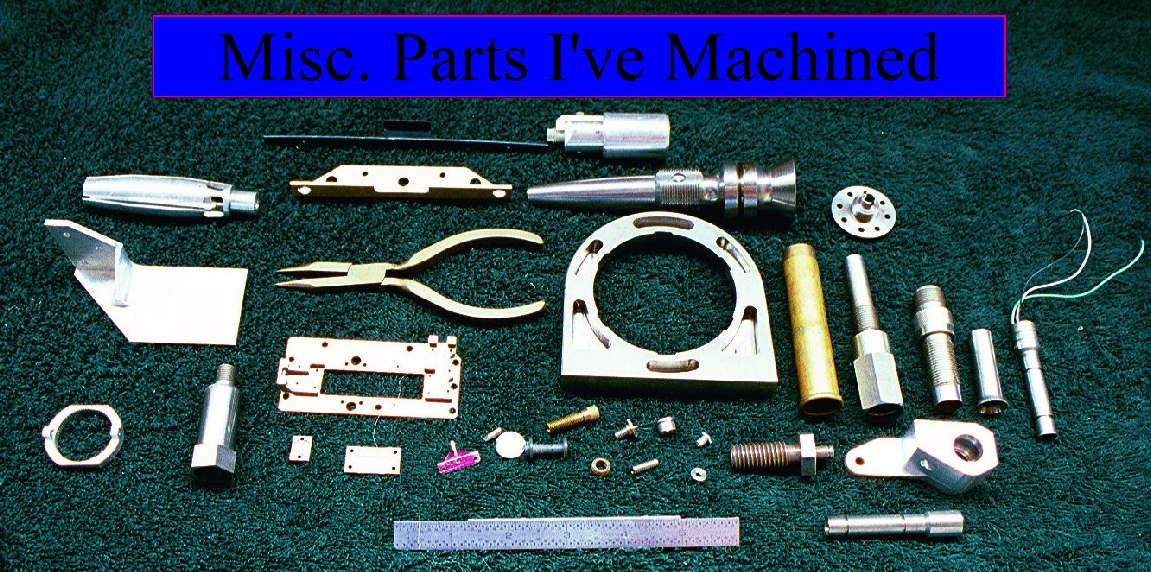

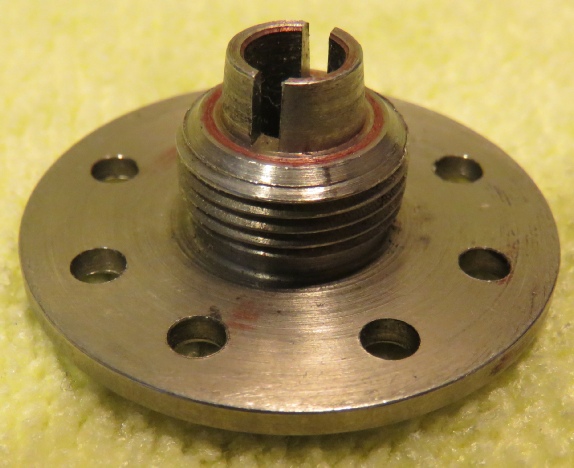

Mat’l: 303 Stainless Steel

Method: Lathe & Mill

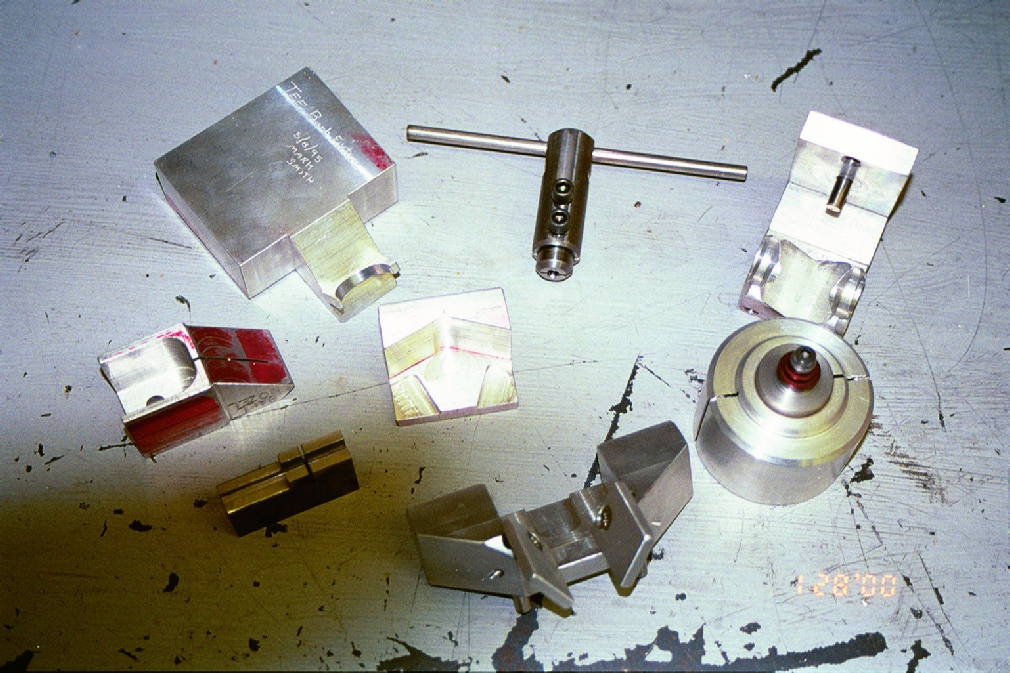

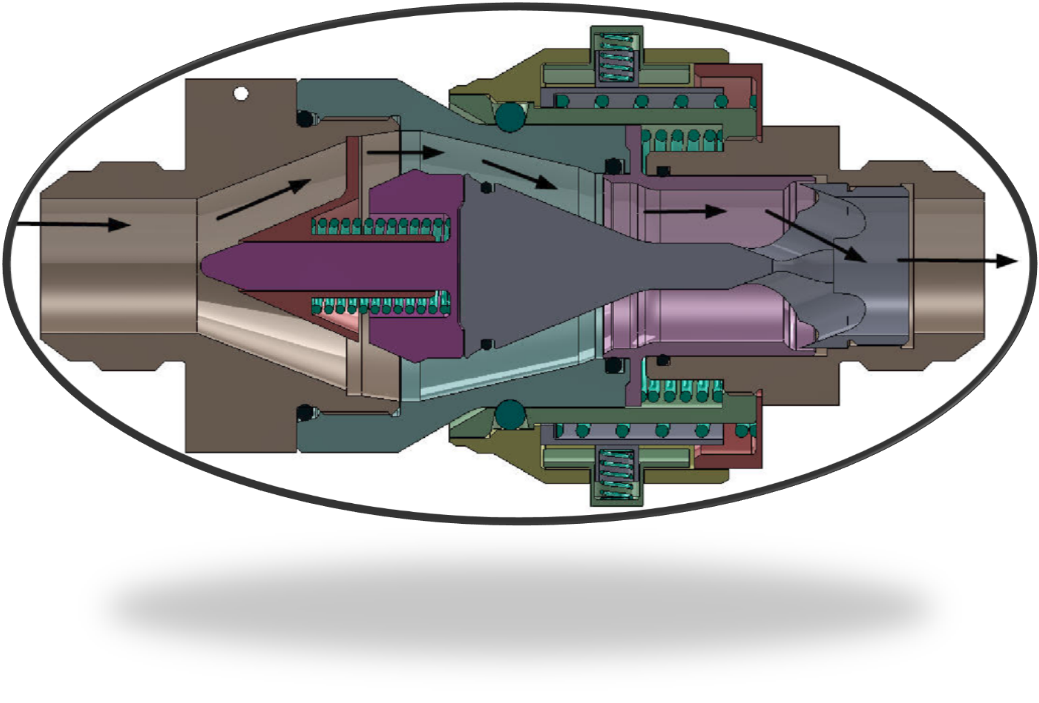

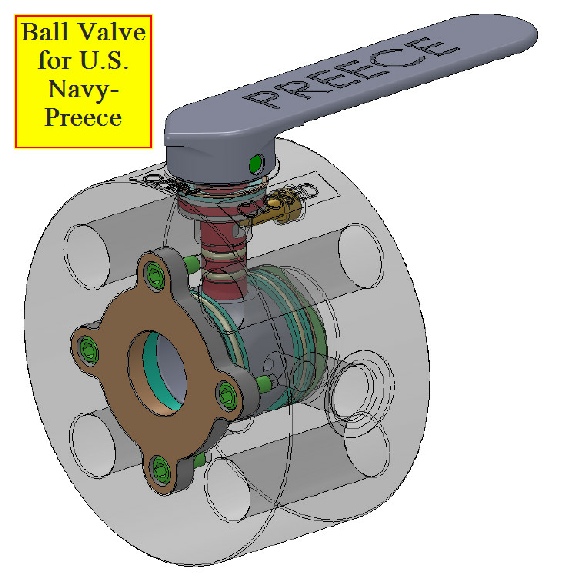

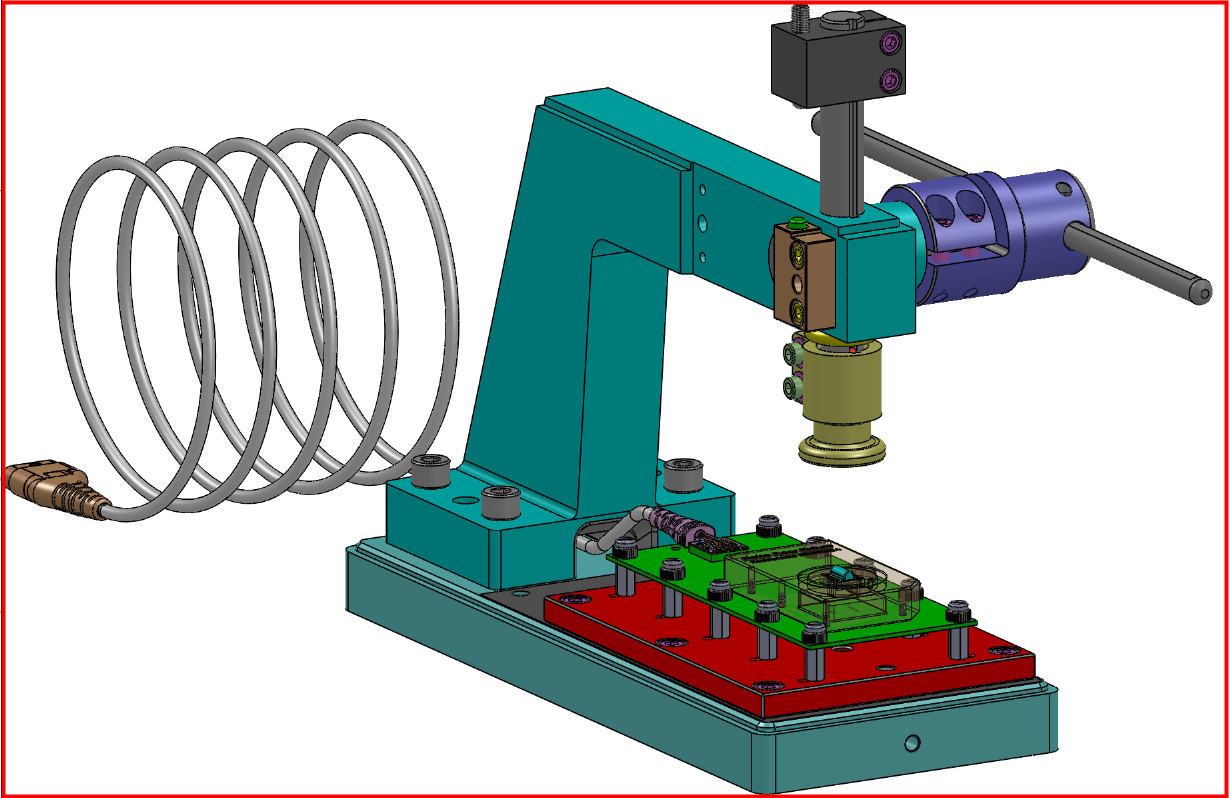

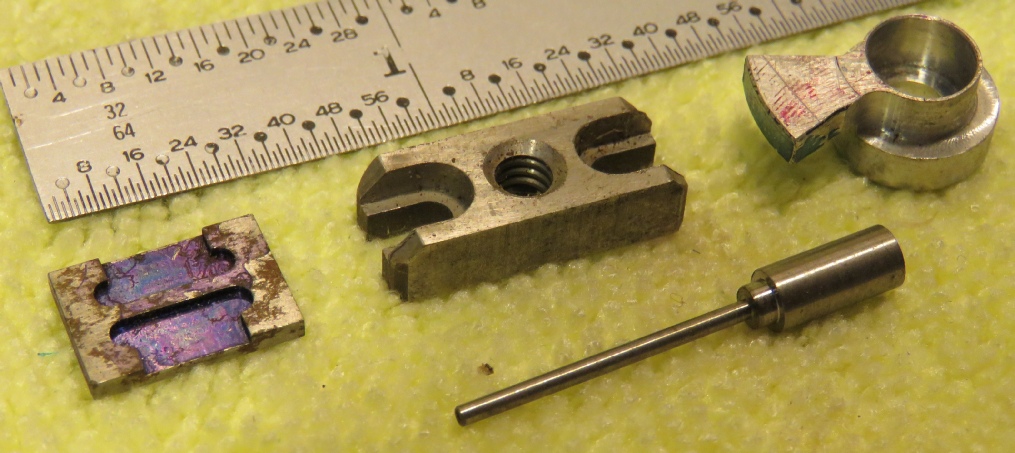

Mat’l: 304 Stainless Steel

Method: 3 Axis Lathe w. Live Tooling

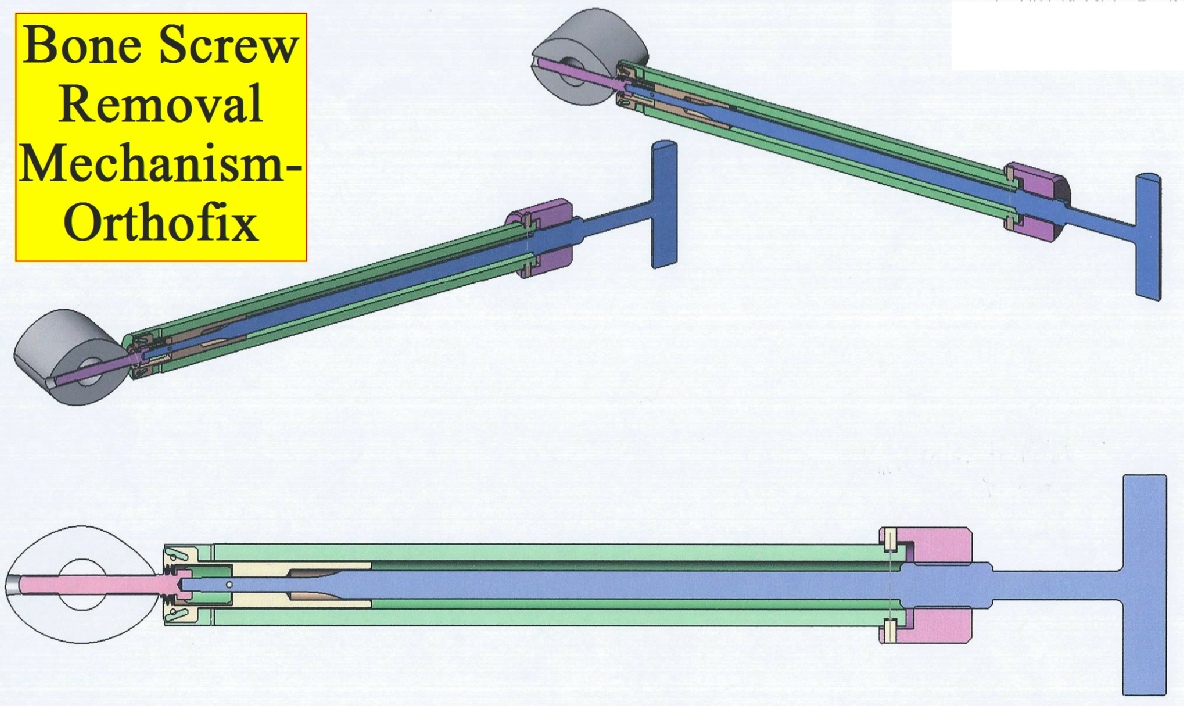

Slide Hammer

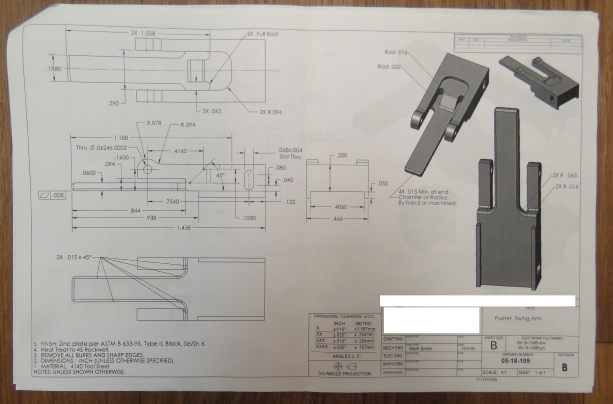

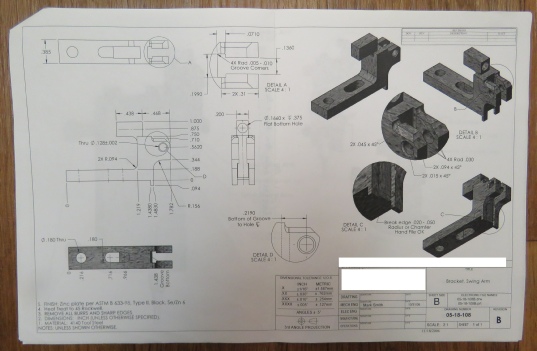

Mat’l: 4140 Tool Steel

Method: Manual Lathe

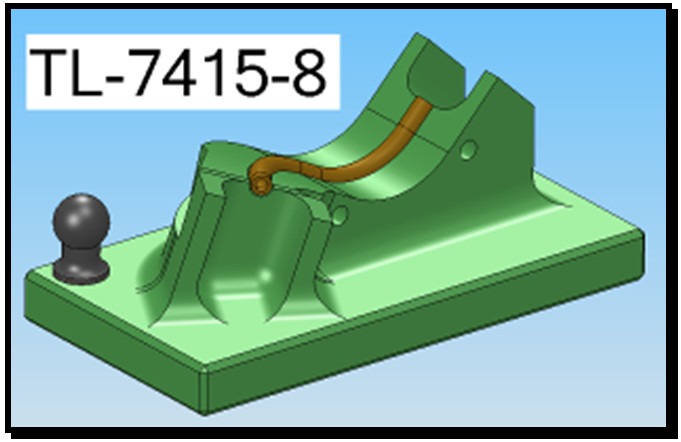

Fixture: For Lathe to Drill Off-

Mat’l: Brass

Method: Deep Drawn Metal Stamping

Mat’l: Kovar

Req: Thin Walled & Flat w/i .001”